What a rotating joint

ROTARY JOINT

The Rotary Joint is a precision device used to transfer fluid under pressure or vacuum from a stationary part to a rotating one. This device guarantees the sealing between a fixed supply (such as a pipe) and a rotating part (such as a roller, a cylinder, a mandrel etc. etc) to allow the flow of a fluid entering and / or leaving the rotating part. Fluids typically used with rotary joints include thermal conditioning fluids (water, coolants, steam, diathermic oil) and power transmission fluids (air, vacuum, water, hydraulic oil).

The Rotary Joint is a precision device used to transfer fluid under pressure or vacuum from a stationary part to a rotating one. This device guarantees the sealing between a fixed supply (such as a pipe) and a rotating part (such as a roller, a cylinder, a mandrel etc. etc) to allow the flow of a fluid entering and / or leaving the rotating part. Fluids typically used with rotary joints include thermal conditioning fluids (water, coolants, steam, diathermic oil) and power transmission fluids (air, vacuum, water, hydraulic oil).

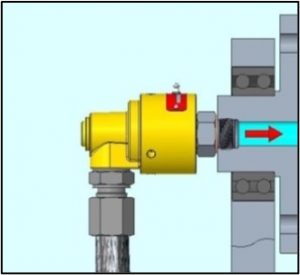

The rotating joint is designed to rotate around an axis, to contain and transfer fluid without leaks to the outside. The design may change, depending on the required application (for high or low pressures, for the number of revolutions and for the number of independent passages).

We will highlight some of the components in a rotating joint:

BODY

The body (generally the static part) is the component that holds together all the other elements of the rotating Joint. It is equipped with one or more inlet ports, generally threaded, to which the flexible inlet / outlet pipes of the fluid, connect. In the case of several ports, in multiway joints, part of these ports will be used to introduce fluid, and part to extract fluid from the component, downstream the installed rotary joint.

ROTOR

The shaft / rotor is the part that carries the fluid through its connection to the downstream cylinder / roller or machinery. The rotor can be threaded or flanged and will generally rotate with the cylinder / roller. In the case of a threaded rotor, care must be taken that the direction of rotation favors the locking of the coupling; for this reason, a thread with clockwise screwing (RH) must be choosen, when the rotation of the cylinder / roller is anticlockwise, (looking at the components from the rear side of the rotary joint), one with anticlockwise screwing (LH) when the rotation is clockwise.

BEARINGS

An important part of the rotating joint are the bearings, which can be of various types. Generally ,they are ball bearings: they have the important task of keeping the joint aligned during rotation. Some rotating Joints have sealed bearings, pre-lubricated for life at the factory; others have the body equipped with a lubrication fitting (grease nipple) and periodically must be re-greased to restore the lubricant. Other rotary Joints have bearings without rolling parts; example of this last ones are the high temperature rotary joints , that use graphite sleeve bearings.

TIGHTNESS

The heart of the rotating Joint is the seal, which has the task of preventing the fluid from escaping from the joint itself during operation. Rotating Joints use different types of sealing arrengements, which can however be summarized in three main types: face type mechanical seal (generally carbon against a hard surface), radial seal (generally in plastic material, energized by O-Rings or metal springs), labyrinth seal.

The rotary Joints for water of the GR series use balanced mechanical seals in Carbon against Silicon Carbide, because this coupling of materials guarantees a longer life; when using oil some models use Tungsten Carbide / Tungsten Carbide coupling (GD series , ..). Others use composite radial seals (GSN series, GHR ..) and others use labyrinths (7750 series), depending from the fluid type that needs to be sealed.

TYPES OF ROTATING JOINTS

The Rotary Joints are mainly differentiated on the basis of the number of passages, the type of fluid, the operating conditions (operating pressure and temperature, rotation speed), the working environment and the intended use (food and non-food). Many assembly lines use multiple rotary Joints, because they are highly versatile and take up less space than other devices designed for a similar purpose. Rotating Joints are also in use in the automotive industry and in other operating machines that require constant supplies of lubrication, air or other fluids, so that the moving parts may work smoothly. Rotary Joints are used in plastics plants, in the paper and printing industry, in the chemical industry, in food and pharmaceutical applications, in agricultural equipment, in washing plants, in steel-mills, in the textile, rubber, packaging, machine tools, in automation and robotics industries … anywhere.